November 3, 1982

Our Articles of Incorporation were granted by the state of Pennsylvania; shortly thereafter, our first rotomolding operation began in Conshohocken, PA.

1984

We began working with chemical handling companies to design and develop containers for chemical storage, transport and dispensing.

1985

We revolutionized the plastic combo bin by creating the reinforced lip, sometimes called the “R” (for Remcon) lip. All competitive designs had a top lip consisting of a flat or rolled exterior flange. Remcon’s engineers noticed that the failure of most bins started with the cracking of this external flange. Studying the problem, we realized that when loaded bins were placed alongside one another, the lip of one bin got caught on top of the bin next to it, causing the lip to be forced upward and putting incredible stress on the material, leading to eventual breakage. By replacing this geometry with a solid, reinforced bead along the top rim that did not extend beyond the side walls, we created a bin with useful life 8-10 times longer than competitive products.

1986

We introduced the first rectangular hopper to transition into a conical bottom discharge opening. This innovation maximized the useful volume of any given sized container by 8%, while ensuring uniform flow.

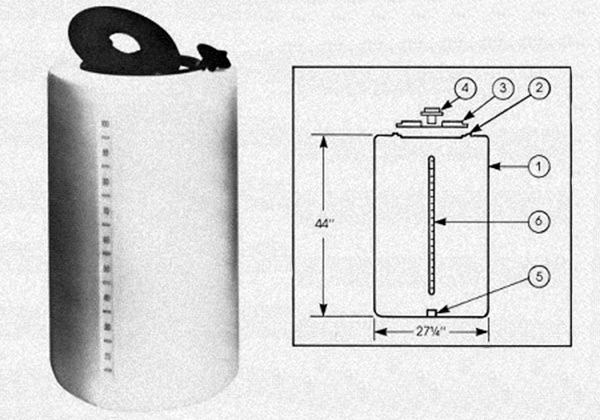

Creating a New Product

In order to help a customer maximize warehouse space, Remcon introduced a square drum. We recognized that round containers do not make efficient use of floor space. By making a square drum, we were able to give our customers 20% more storage in the same floor space.

Contract Manufacturing

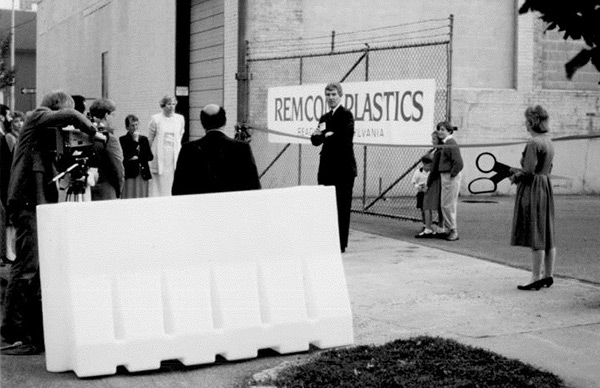

Remcon creates the industry standard for water-filled plastic road barriers. Leo J. Yodock approached us after prototypes of his plastic road barrier failed to perform as required. In response, we developed a design that passed all DOT tests, and subsequently became the industry standard because of its superior performance.

1990

Mayor Warren Haggerty welcomes Remcon to Reading, PA during the dedication ceremony of Remcon’s new facility.

1991

While designing products for a start-up business, we help to develop the industry standard for secondary containment systems under gas stations. In order to meet environmental regulations, the gasoline retail industry had to encapsulate all underground tanks and piping with a second layer of containment equipped with leak detection monitors. Remcon developed a broad range of products to interface with prevailing dispensing equipment.

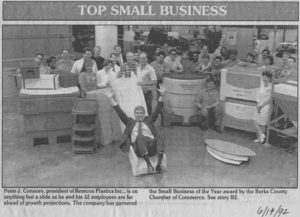

1992

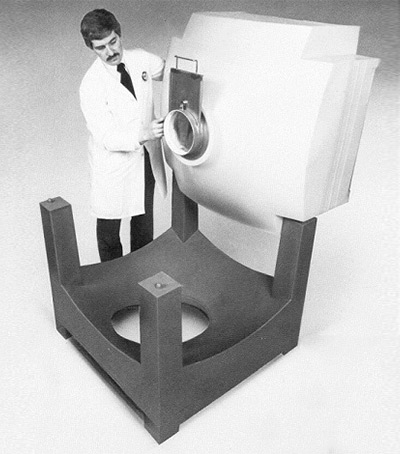

Responding to a candy maker who wanted to reduce cooling time of the “panned” jawbreakers, we develop a unique cooling hopper that forces air through a bulk container to cool the jawbreakers. Cooling time was reduced by 75%, with a similar reduction in work-in-process inventory, and reduced floor space requirements more than 50%.

Remcon closes out our first decade with The Best Small Business of the Year Award from the Berks County Chamber of Commerce.